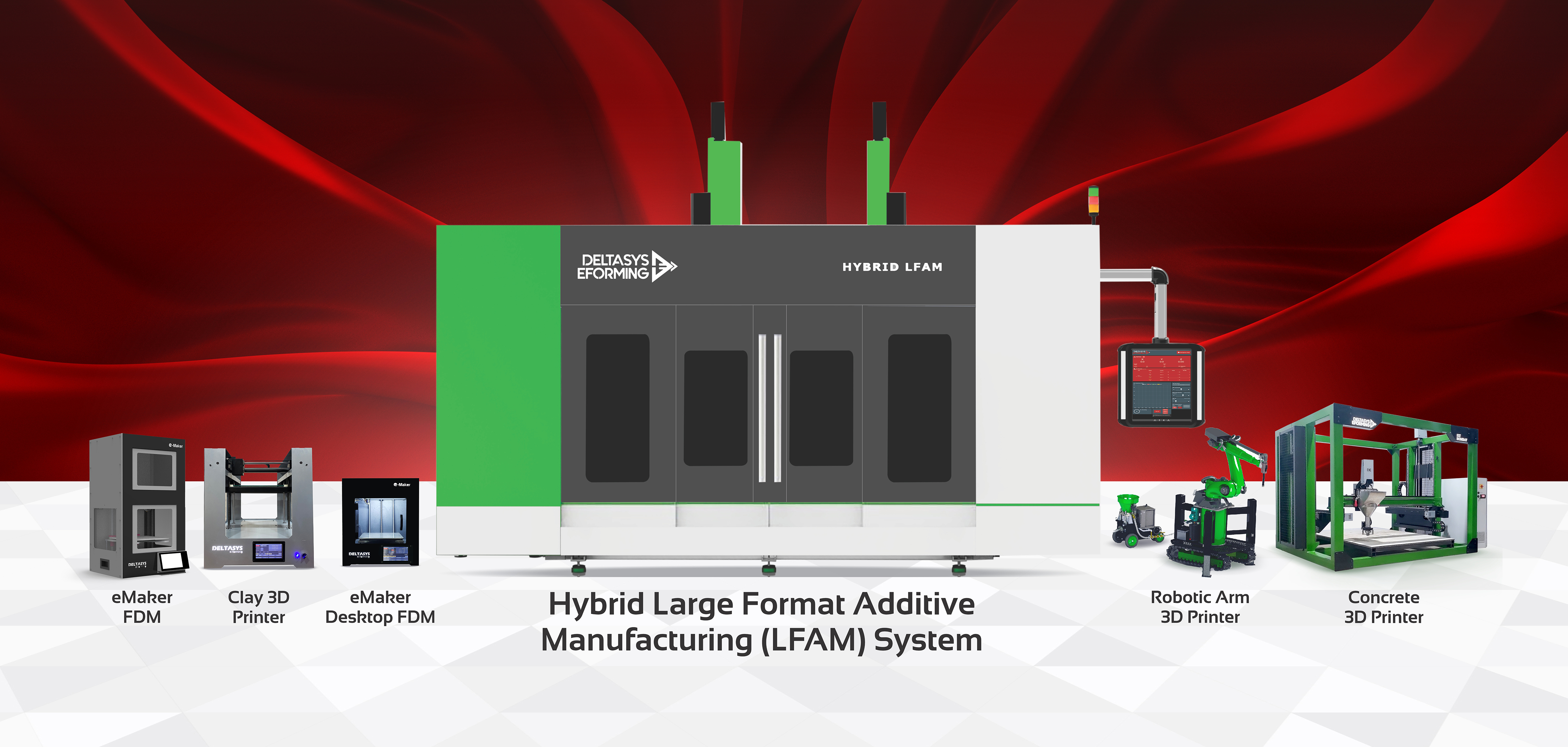

Hybrid Large Format Additive Manufacturing (LFAM) System

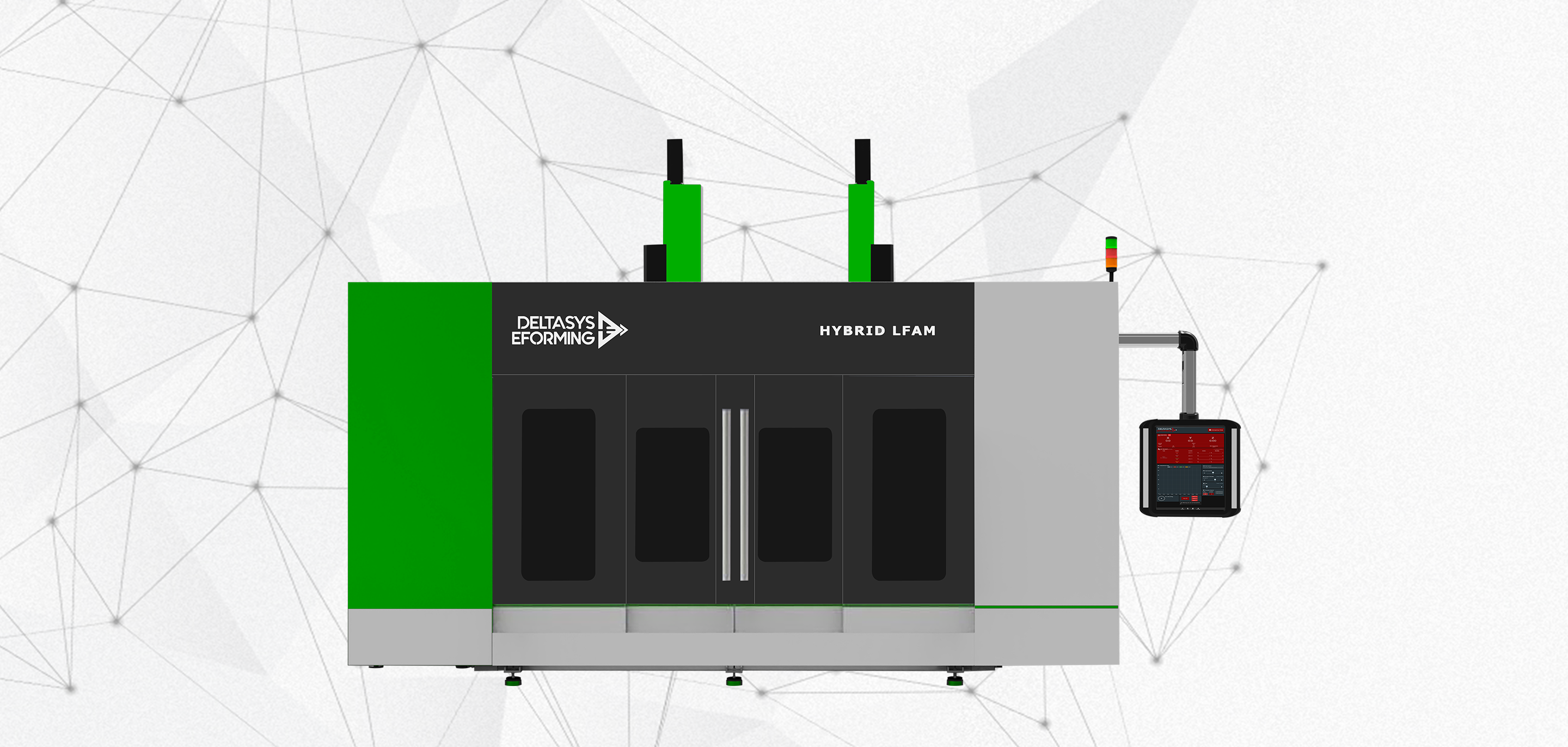

What is Hybrid Large Format Additive Manufacturing?

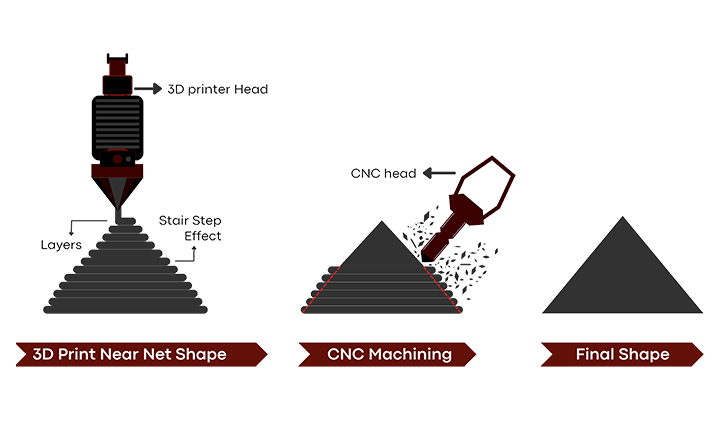

Hybrid LFAM uses the “Near Net Shape” approach to part production where the part is first printed at high speed slightly larger than needed, then trimmed to the final size and shape. This is the fastest, most efficient method of 3D printing large structures. With LFAM, both printing and trimming can be done on the same machine. LFAM can process parts from virtually any thermoplastic composite material including high temperature materials that are ideal for moulds and tooling that must operate at elevated temperatures.

LFAM’s printing system produces parts that are solid, fully fused, vacuum tight and virtually void free. LFAM is intended for serious industrial production. It is not a lab, evaluation or demonstration machine, but is instead a full-fledged industrial additive manufacturing system intended for the production of large scale components.

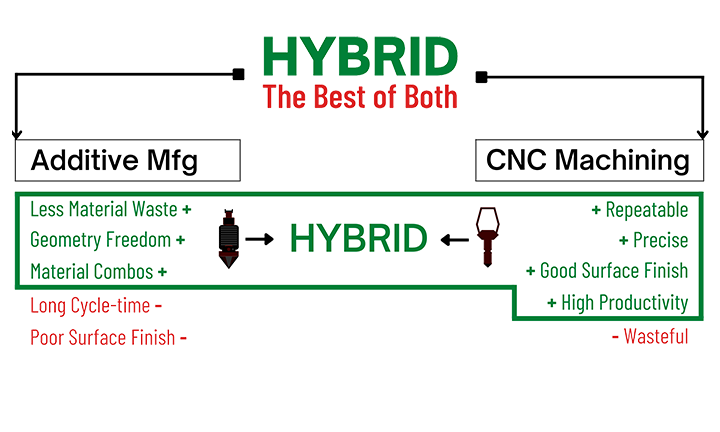

Advantage OF Hybrid LFAM :

Only LFAM Cannot deliver the finish and tolerances which CNC Machining offers. On the other hand, traditionally parts have been made by machining an oversized blank, removing material to achieve the final net shape. Often more material is removed than remains. Near-net-shape additive manufacturing prints a part that is nearly the final size and shape then trims it to final dimensions. The amount of material removed is much less, resulting in faster processing, lower cost and more efficient use of material. It is an ideal approach for really large parts where alternate production methods may not be possible. With the proper choice of material, it may be possible to skip building a master and go directly from a computer design to printing a working mould, saving even more time and money. For industrial tooling, this direct digital, additive manufacturing approach is substantially faster and dramatically less expensive.

Application(List)

- ⦁ Tooling such as Mould and Patterns

- ⦁ Composite Patterns and Moulds

- ⦁ Packaging industry for custom packing

- ⦁ Recreational vehicles

- ⦁ Concrete moulds for construction

- ⦁ Jigs and Fixture

- ⦁ Electric vehicles

- ⦁ Unmanned Aerial Vehicle (UAV)

- ⦁ Furniture’s

- ⦁ Interior designing

- ⦁ Wall panels

- ⦁ Defense

- ⦁ Aerospace

- ⦁ Automotive

- ⦁ Boat

- ⦁ Railway

- ⦁ Toolrooms

- Software :

The process starts with a 3d computer model of the part. This design in an industry standard solid, surface or mesh file format, is loaded in to our print software. The 3d computer model is then used to generate a print and trim program which is used for printing and trimming

The process starts with a 3d computer model of the part. This design in an industry standard solid, surface or mesh file format, is loaded in to our print software. The 3d computer model is then used to generate a print and trim program which is used for printing and trimming

- Printing :

The printing process consists of heating (Carbon or Glass) fiber reinforced thermoplastic material until it is soft and pliable and then laying it down as a continuous bead layer by layer until the part shape has been generated. Each new layer fuses with existing layers to produce solid, strong, void free part.

The pelletized thermoplastic material is first dried to remove any moisture and then pneumatically conveyed to a vertically mounted print head. the print head heats the material to a softened state and meters the material at precise controlled rate through a print nozzle. This advanced print head design automatically coordinates with machine motion to maintain precise print bead dimensions, even at very high print rates.

.

The printing process consists of heating (Carbon or Glass) fiber reinforced thermoplastic material until it is soft and pliable and then laying it down as a continuous bead layer by layer until the part shape has been generated. Each new layer fuses with existing layers to produce solid, strong, void free part.

The pelletized thermoplastic material is first dried to remove any moisture and then pneumatically conveyed to a vertically mounted print head. the print head heats the material to a softened state and meters the material at precise controlled rate through a print nozzle. This advanced print head design automatically coordinates with machine motion to maintain precise print bead dimensions, even at very high print rates.

.

- Trimming :

DE LFAM trimming is accomplished using three axis CNC Router mounted on separate gantry which rides on the same overhead rails as the print gantry (the 5axis trim head is available as optional, it depends on the customer’s application & parts complex geometry). It uses 6kw 3000 to 24000 rpm manual tool change spindle. (Automatic tool change is optional with ten tools linear magazine).

DE LFAM trimming is accomplished using three axis CNC Router mounted on separate gantry which rides on the same overhead rails as the print gantry (the 5axis trim head is available as optional, it depends on the customer’s application & parts complex geometry). It uses 6kw 3000 to 24000 rpm manual tool change spindle. (Automatic tool change is optional with ten tools linear magazine).

The Process

Our 3D Printers benefits

3d printers buyers guide

The Industrial 3D Printer Price

While much attention has been focused on the consumer market, consumer-grade 3D printers are not suitable for large-scale production grade additive manufacturing. Industrial 3D printers are designed for a specific purpose and they have the speed, facilities and robustness which are critical for industrial 3D manufacturing.

They come with a wide range of features and different specifications, that means that the industrial 3D printer price can vary hugely. To identify just how much industrial printers cost, it is worth understanding a little more about them. What is the difference between the consumer 3D printer and industrial 3D printer price and why? Where is it based on and how to compare?

What is the difference between the consumer 3D printer and industrial 3D printer price

Industrial printers are designed to be used in an industrial setting. This means that they are engineered to print in a different way and they have a higher output of precision and accuracy. Consumer 3D printers are simpler in design and used to create easier models that use less durable materials. Let's have a look at the main difference so you understand better why the Industrial 3d printer price is always slightly higher.

The different features

- Applications : The big difference in use is often down to the specific construction parameters of both devices. 3D printers that are designed for use in an industrial setting are more advanced as they enable the printing of fully functioning prototypes. Therefore, they are ideal for printing tools and instrumentation. This also means that the creation of a final product is possible using 3D printing. Consumer 3D printers are designed for different applications. These 3D printers are less advanced and are best used for creating simple models using less durable materials. This means that they are ideal for someone who wants to create individual elements which are not very complicated and do not require high precision or certain physical features.

- Closed chamber (enclosure) : For those businesses that need the use of more demanding (high-performance) materials, industrial 3D printers come with enclosed chambers. This makes it possible to print at a temperature that is higher and stable which is a requirement for certain print materials. Most consumer 3D printers don’t have a closed chamber, so there are more temperature fluctuations while 3D printing. Therefore you can only use a limited choice of print materials and you have to compromise on the quality of your prints as well. The presence of a casing will result in a higher consumer and/or industrial 3D printer price.

- Assembled or DIY-kit : Consumer 3D printers are available as assembled units or Do It Yourself (DIY) kits. Hobbyist which have the technical knowledge and enough time, are happy to build a printer themselves. Of course, this makes the purchase of the consumer printer cheaper compared to the industrial 3D printer price. Industrial 3D printers on the other hand are delivered fully assembled, and often ready to print by arrival. In some cases this is not possible, for example because of the large size of the printer and shipment restrictions. In that case the industrial 3D printer manufacturer often offers a service of installation on location. An engineer of the manufacturer will take care of installing the printer on site.

- Single or Dual extrusion : As mentioned, consumer 3D printers are simpler build than professional 3D printers and that is why the industrial 3D printer price is a bit higher. Having the ability to print complex models and using support material is all down to the quality of the printer and software settings. Also the number of extruders (print heads) can play a part here. If you have a single head extruder, you can print one material. When you are printing with one material, PLA for instance, it is sometimes difficult to break the supports away from the model. This can cause damage and leave traces that can prove difficult to remove. If supports are printed using a different material to that of the main model, for example water-soluble (PVA) material, it often makes it easier to remove it and reduces the risk of damage and chipping. In this case you need two extruders (dual head), which also influences the industrial 3D printer price.

- Process Automation : A consumer 3D printer can be reliable up to a point, but it is limited in what it can design. It does not have the same functions as an industrial 3D printer. Even though, in some cases, these functionalities are not necessary. When it comes to printing a complex object, these additional features such as automatic build plate calibration or out-of-filament sensor, will become a useful option. When printing with a consumer 3D printer, there is a lot to think about, that means that the print time increases and the chance of errors is higher.

- Implementation costs : When a company considers investing in an industrial 3D printer, the cost of printing with a 3D printer and how it can benefit the business will be ascertained. We will later in this article proof to you that implementing a 3D printer into an industrial environment can deliver significant costs savings, helps to save time and improve productivity. Using a 3D printer can require a bit of training, which is something that you do not get with a consumer 3D printer because of the way in which they operate as well as their capabilities. In an industrial environment, it is important to understand the potential problems, solutions as well as determining how to ensure a successful print each time. With a consumer 3D printer, there is often no real level of support as users are left to test everything themselves.

- Availability of materials : There are many different materials available to print with when using an industrial 3D printer. However, when using a simple consumer 3D printer, the more demanding materials are often not suitable for use. Printers that have been designed for industrial use can handle many different materials like HIPS, ASA, PC-ABS, Nylon (PA) and even the high temperature thermoplastics such as PEEK and PEI/ULTEM. The industrial 3D printer price is a little higher because of this, but it will give companies more design freedom to meet their specifications.